Galvashield XP

Tie on Sacrificial Anode units for corrosion prevention

Description:

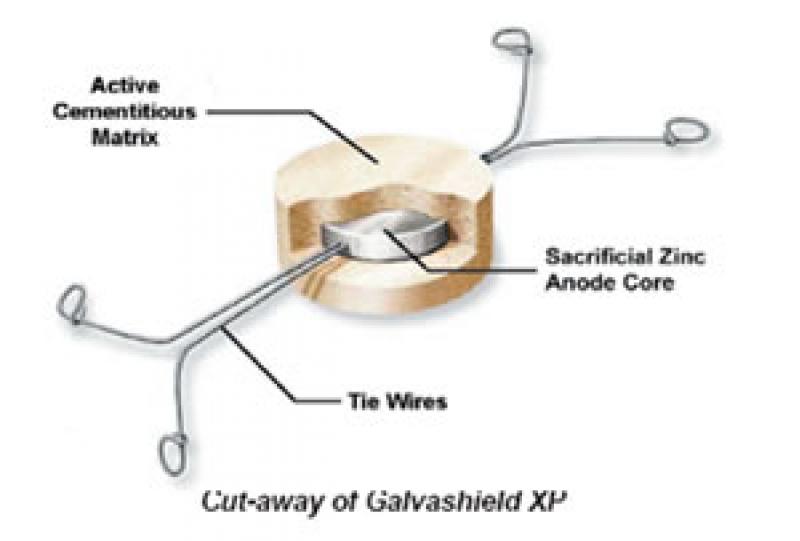

Galvashield XP embedded galvanic anodes are used in concrete rehabilitation to prevent the formation of new corrosion sites on adjacent rebar. The anode consists of a sacrificial zinc core activated within a specially formulated cementitious mortar. The XP unit is fixed to the reinforcing steel by means of tie wires, which allow attachment in horizontal, vertical and overhead locations. Once installed, the zinc core corrodes preferentially to the surrounding rebar, providing ‘Cathodic Prevention’ and therefore preventing ‘Incipient Anode’ formation.

Typical Applications:

- Patch Repairs

- Joints between new and existing concrete

- Pre-stressed Concrete

- Post-tensioning anchors

Advantages:

- Proven technology - supported by independent test programs. British Board of Agrement and Concrete Innovations Appraisal Service (USA)

- Quick and easy installation - requiring no special equipment or training.

- Zero Maintenance - Requires no external power source or monitoring.

- Measurable - Anode performance can easily be monitored if required.

- Versatile - Suitable for chloride contaminated, pre-stressed/ post tensioned and new concrete.

- Up to 20 years life - Reduces the need for future repairs.

How it works:

Galvashield anodes work on the principle of sacrificial protection. When two dissimilar metals are placed in an electrolyte (in this case within concrete) the most active metal (zinc) will sacrifice itself to protect the more noble (less active) reinforcing steel. Galvashield XP anodes are embedded in patch repairs to provide Cathodic Prevention to the reinforcing steel immediately adjacent to the repair area. They will prevent secondary corrosion to the steel, commonly referred to as the ‘Incipient Anode’ or ‘Ring Effect’.

Independently certified performance. British Board of Agrement Certificate (No. 04/4140) Dependent upon XP design and structure.

Specification Claus:

The sacrificial anode shall be Galvashield XP, a sacrificial metal surrounded by a highly alkaline cementitious mortar, which has a pore solution pH sufficiently high for corrosion of the anode to occur and for passive film formation on the anode to be avoided as described in patent number WO94/29486PCT.

Application:

Break out the concrete from around and behind the steel reinforcement in accordance with good concrete repair practice. All exposed steel reinforcement should be cleaned to a bright condition paying particular attention to the back of exposed steel bars. Abrasive blasting is recommended for this process. Prior to installation of the XP units, check the continuity of the steel reinforcement. Any loss of continuity will require additional electrical connections or restoration of continuity by effective means.

Select a location for the Galvashield XP as close as practical to the edge of the broken out repair zone and excavate a rebate as required. Galvashield XP units should be positioned around/along the repair boundary. In addition to standard substrate preparation, the Galvashield XP anode(s) shall be thoroughly pre-soaked in clean water for a minimum of 10 and a maximum of 20 minutes, prior to the application of the repair mortar.

Attach the Galvashield XP anodes immediately following preparation and cleaning of the steel reinforcement. The anode spacing shall be in accordance with the repair specification. Tighten tie wires using Galvashield Fixing Tool so that no free movement is possible, thus ensuring good electrical continuity.

To test electrical continuity between tie wires and reinforcement bar a continuity meter should be used. A value between 0.1 - 1 Ohm shall be achieved. When required the steel reinforcement should be primed immediately following attachment of the Galvashield XP with a 135 micron (wft) continuous coating of Nitoprime Zincrich Plus.

Over painting with the bonding agent or reinforcement primer, onto the surface of the Galvashield XP unit must be avoided. The Galvashield XP should be positioned to ensure all round contact with the reinstatement material preventing void formation. Cover to the Galvashield XP should equal the depth of cover to the steel reinforcement to which it is attached.

In no case shall it be less than 20mm for horizontal repairs or 10mm for vertical and overhead repairs

Steel Surface Area Maximum Spacing Between XP Units (A)

per m2 of concrete

<0.6 610mm

0.61 - 0.9 500mm

0.91 - 1.2 430mm

Level of Protection Description Galvashield XP:

Cathodic Prevention Preventing new corrosion activity from initiating

Corrosion Control:

Significantly reduce ongoing corrosion activity

Cathodic Protection:

Highest level of protection, intended to stop ongoing corrosion.

The Galvashield XP should be used in conjunction with Fosroc's extensive range of compatible repair mortars and acrylic bonding/curing agents.

Galvashield XP is not suitable for use with epoxy and polyester repair mortars or primers, as these are non conductive Blanket galvanic protection of sound but contaminated areas of concrete can be established by the use of Galvashield CC sacrificial anodes (refer to Galvashield CC data sheet).

Galvashield XP 64mm diameter x 27mm thick 20 units per pack

Store in dry conditions in the original unopened box. Shelf life 12 months - see package instructions for details.

Nitoprime Zincrich Plus must be stored in accordance with the Highly Flammable Liquids and Liquefied Petroleum Gases Regulations 1972.

All wastewater used to pre-soak Galvashield XP units must be mixed with a cementitious material before disposal. Once cured dispose in accordance with local regulations.

Galvashield XP should be handled using protective gloves, and other personal protective equipment, as per standard procedures for handling cementitious materials.